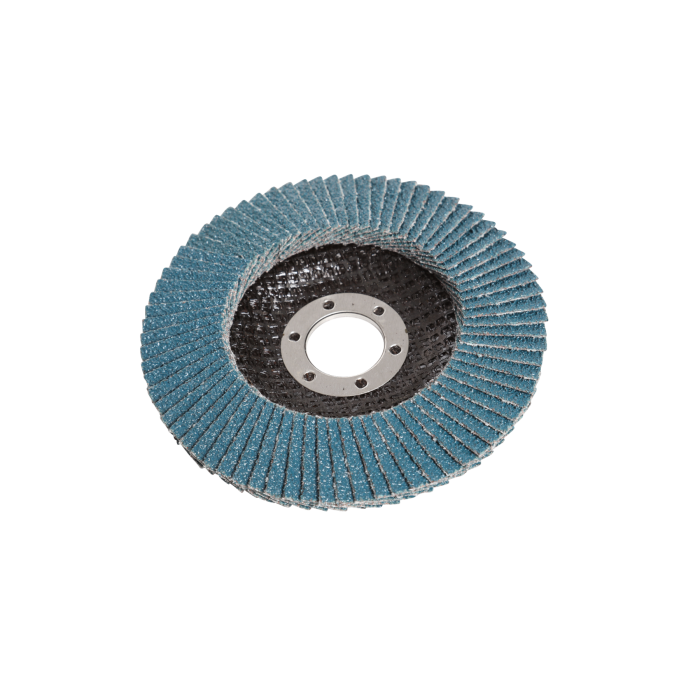

| Why use a Zirconium Flap Disc 115Mm 60 Grit 10 Discs Per Pack |

| |

| 1. Balanced Cutting Power & Surface Finish |

| |

| 60 grit offers a medium-coarse abrasive, ideal for blending, smoothing, and moderate material removal. |

| |

| Removes welds and imperfections while leaving a finish that often needs minimal further sanding or polishing. |

| |

| |

| |

| 2. Long-Lasting Zirconium Abrasive |

| |

| Zirconium oxide is tougher and more durable than aluminum oxide. |

| |

| Self-sharpening: abrasive grains fracture during use to continually expose fresh cutting edges. |

| |

| |

| |

| 3. Cooler Grinding |

| |

| Flap design + zirconium grain = lower heat buildup, reducing the risk of warping or discoloring metals. |

| |

| Especially useful on stainless steel and heat-sensitive alloys. |

| |

| |

| |

| 4. Versatile 115mm (4.5") Size |

| |

| Fits standard angle grinders. |

| |

| Great for flat surfaces, curved edges, and working in tighter spaces. |

| |

| |

| |

| 5. Cost-Effective in Packs of 10 |

| |

| Bulk packs offer better value and ensure you always have replacements ready. |

| |

| Ideal for shops or projects requiring consistent performance and availability. |

| |

| |

| |

| 6. Multi-Material Compatibility |

| |

| Effective on: |

| |

| |

| |

| Mild steel |

| |

| Stainless steel |

| |

| Cast iron |

| |

| Non-ferrous metals like aluminum and brass (with care) |

| |

| |

| |

| The benefits of a Zirconium Flap Disc 115Mm 60 Grit 10 Discs Per Pack |

| |

| 1. Ideal Balance of Material Removal and Finish |

| |

| 60 grit provides a medium-coarse cut, making it perfect for: |

| |

| |

| |

| Moderate stock removal |

| |

| Blending welds |

| |

| Smoothing rough surfaces |

| |

| Leaves a cleaner finish than 40 grit, reducing the need for follow-up sanding. |

| |

| |

| |

| 2. High-Performance Zirconium Grain |

| |

| Zirconium oxide is more durable and longer-lasting than standard aluminum oxide. |

| |

| Self-sharpening grain means it maintains cutting performance over time, especially under pressure. |

| |

| |

| |

| 3. Cooler Cutting Action |

| |

| Flap discs generate less heat than grinding wheels. |

| |

| Zirconium stays cool, making it ideal for heat-sensitive metals like stainless steel and aluminum (with care). |

| |

| |

| |

| 4. Efficient and Long-Lasting |

| |

| Flap discs wear evenly, so you use more of the abrasive material before replacement is needed. |

| |

| Offers greater lifespan and consistency compared to fiber or resin discs. |

| |

| |

| |

| 5. Versatile 115mm Size |

| |

| Fits standard 4.5” angle grinders. |

| |

| Great for both flat surfaces and detailed edge work in tight areas. |

| |

| |

| |

| 6. Multi-Material Capability |

| |

| Suitable for: |

| |

| |

| |

| Mild steel |

| |

| Stainless steel |

| |

| Cast iron |

| |

| Aluminum (with correct technique) |

| |

| |

| |

| 7. Cleaner, Smoother Finish |

| |

| Produces a smoother surface than coarse 40 grit, making it suitable for finishing work. |

| |

| Reduces or eliminates the need for a second sanding step before painting or coating. |

| |

| |

| |

| 8. Cost-Effective in 10-Pack |

| |

| Buying in bulk reduces the cost per disc. |

| |

| Keeps your shop or garage stocked and ready for longer jobs or ongoing work. |

| |

| |

| |

| 9. Safer, Quieter Operation |

| |

| Produces less vibration and noise compared to traditional grinding wheels. |

| |

| Safer to use with lower risk of disc breakage under load. |

| |

| |

| Uses and applications of a Zirconium Flap Disc 115Mm 60 Grit 10 Discs Per Pack |

| |

| 1. Weld Blending and Cleanup |

| |

| Smooths and blends weld beads on mild steel and stainless steel. |

| |

| Ideal for post-weld finishing where a cleaner, more polished look is needed without switching to a finer grit. |

| |

| 2. Moderate Stock Removal |

| |

| Removes material faster than fine grit, but with more control and finesse than coarse (40 grit) discs. |

| |

| Great for shaping edges and reducing high spots. |

| |

| 3. Surface Preparation |

| |

| Prepares metal for: |

| |

| |

| |

| Painting |

| |

| Powder coating |

| |

| Welding |

| |

| Cleans up mill scale, oxidation, and light rust effectively. |

| |

| 4. Smoothing and Finishing |

| |

| Leaves a smoother finish than 40 grit, often suitable as a final step before coating. |

| |

| Excellent for cosmetic prep work where appearance matters. |

| |

| |

| |

| Typical Applications |

| |

| Automotive Repair and Fabrication |

| |

| Body panel prep and weld blending on cars, trucks, and motorcycles. |

| |

| Used in both restoration and custom fabrication. |

| |

| Metal Fabrication Shops |

| |

| Smoothing and shaping fabricated parts. |

| |

| Used during both intermediate and finishing stages of metalwork. |

| |

| Industrial Maintenance |

| |

| Cleaning parts for repair or refurbishment. |

| |

| Preparing surfaces for painting or sealing in equipment maintenance. |

| |

| DIY and Home Garage Projects |

| |

| Used by hobbyists for light fabrication, metal art, or home-based repairs. |

| |

| Offers a good balance between aggressive cutting and surface quality. |

| |

| |

| |

| Materials It Works Well On |

| |

| Mild steel |

| |

| Stainless steel |

| |

| Cast iron |

| |

| Aluminum (with care to prevent clogging) |

| |

| Non-ferrous metals like brass or copper |

| |

| |

| |

| Why 60 Grit Zirconium? |

| |

| Offers a middle ground: more aggressive than 80 grit, smoother than 40. |

| |

| Ideal for general-purpose grinding and finishing. |

| |

| Zirconium is self-sharpening, meaning longer lifespan and consistent performance. |