|

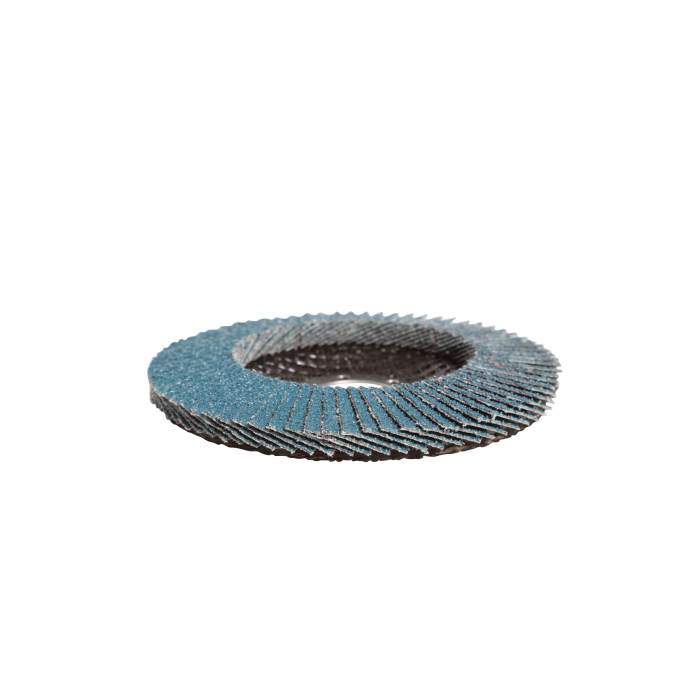

Why use a Zirconium Flap Disc 115MM 40 Grit 10 Discs Per Pack

|

|

|

|

1. Aggressive Material Removal (40 Grit)

|

|

|

|

40 grit is a coarse grit, perfect for heavy stock removal, weld grinding, and surface leveling.

|

|

|

|

Removes rust, paint, and burrs quickly on steel and other hard materials.

|

|

|

|

2. High-Performance Zirconium Grain

|

|

|

|

Zirconium is tougher and lasts longer than aluminum oxide.

|

|

|

|

Self-sharpening abrasive grain: as it wears, new sharp edges are exposed.

|

|

|

|

Ideal for stainless steel, mild steel, and harder alloys.

|

|

|

|

3. Durable and Long-Lasting

|

|

|

|

Flap discs wear evenly, extending disc life compared to traditional fiber or grinding discs.

|

|

|

|

You get consistent cutting performance over time.

|

|

|

|

4. Versatile 115mm (4.5") Size

|

|

|

|

Fits most standard angle grinders.

|

|

|

|

Suitable for tight spaces and detailed work while still covering enough surface area for efficiency.

|

|

|

|

5. Cooler Grinding Action

|

|

|

|

Flap design and zirconium grain reduce heat buildup.

|

|

|

|

Helps prevent metal discoloration or warping, especially on stainless steel.

|

|

|

|

6. Improved Finish Compared to Grinding Discs

|

|

|

|

Leaves a smoother surface that often requires less secondary finishing.

|

|

|

|

Good for preparing surfaces for painting, coating, or welding.

|

|

|

|

7. Cost-Effective in Packs of 10

|

|

|

|

Bulk packs provide better value for high-volume users.

|

|

|

|

Reduces downtime from frequent tool changes.

|

|

|

|

|

|

|

|

Common Applications

|

|

|

|

Weld removal and blending

|

|

|

|

Deburring and edge grinding

|

|

|

|

Surface prep before painting or coating

|

|

|

|

Rust and paint removal

|

|

|

|

Grinding on stainless steel or mild steel

|

|

|

|

|

|

|

|

Industries & Users

|

|

|

|

Fabrication and metal workshops

|

|

|

|

Automotive repair and restoration

|

|

|

|

Shipbuilding and heavy machinery

|

|

|

|

Construction and structural steel

|

|

|

|

DIY users working with metal

|

|

|

|

|

|

|

|

The benefits of a Zirconium Flap Disc 115MM 40 Grit 10 Discs Per Pack

|

|

|

|

1. Fast and Aggressive Material Removal

|

|

|

|

40 grit is coarse and ideal for heavy-duty grinding, weld removal, and surface leveling.

|

|

|

|

Quickly removes rust, scale, paint, and burrs.

|

|

|

|

|

|

|

|

2. High-Performance Zirconium Abrasive

|

|

|

|

Zirconium oxide is tougher and longer-lasting than standard aluminum oxide.

|

|

|

|

Self-sharpening properties mean it stays sharper longer, maintaining cutting power throughout its life.

|

|

|

|

|

|

|

|

3. Versatile 115mm (4.5") Size

|

|

|

|

Compatible with most standard angle grinders.

|

|

|

|

Great for tight spaces and precision grinding as well as general surface work.

|

|

|

|

|

|

|

|

4. Cooler Grinding, Less Heat Build-Up

|

|

|

|

Flap disc design and zirconium composition result in cooler grinding.

|

|

|

|

Reduces risk of discoloring or damaging heat-sensitive metals like stainless steel.

|

|

|

|

|

|

|

|

5. Smoother Finish

|

|

|

|

Unlike standard grinding wheels, flap discs leave a cleaner, smoother finish, often eliminating the need for additional finishing passes.

|

|

|

|

Great for prepping surfaces for paint, coatings, or welding.

|

|

|

|

|

|

|

|

6. Long-Lasting and Durable

|

|

|

|

Flap design ensures even wear, maximizing disc life.

|

|

|

|

More efficient over time compared to fiber discs or bonded grinding wheels.

|

|

|

|

|

|

|

|

7. Cost-Effective Pack of 10

|

|

|

|

Buying in bulk reduces cost per disc.

|

|

|

|

Ideal for high-use environments like workshops and job sites.

|

|

|

|

|

|

|

|

8. Multi-Material Use

|

|

|

|

Excellent on:

|

|

|

|

|

|

|

|

Stainless steel

|

|

|

|

Mild/carbon steel

|

|

|

|

Cast iron

|

|

|

|

Aluminum (with proper care)

|

|

|

|

|

|

|

|

9. Time-Saving

|

|

|

|

Combines grinding and finishing in one step, reducing tool changes.

|

|

|

|

Boosts productivity in busy fabrication or repair settings.

|

|

|

|

|

|

|

|

|

|

|

|

Uses and applications of a Zirconium Flap Disc 115MM 40 Grit 10 Discs Per Pack

|

|

|

|

1. Heavy Material Removal

|

|

|

|

Ideal for grinding down welds, removing large burrs, or cleaning up rough surfaces.

|

|

|

|

Perfect for aggressive stock removal where a smooth finish is not the primary goal.

|

|

|

|

2. Surface Preparation

|

|

|

|

Prepares metal surfaces for:

|

|

|

|

Welding

|

|

|

|

Painting or powder coating

|

|

|

|

Bonding or sealing

|

|

|

|

3. Rust, Scale, and Paint Removal

|

|

|

|

Quickly removes surface contaminants from metal, such as:

|

|

|

|

Rust and corrosion

|

|

|

|

Old paint layers

|

|

|

|

Mill scale

|

|

|

|

4. Beveling and Edge Grinding

|

|

|

|

Effective for creating bevels on metal edges.

|

|

|

|

Can be used to smooth out rough cuts or torch-cut edges.

|

|

|

|

5. Weld Blending

|

|

|

|

Smooths out and shapes welded joints on:

|

|

|

|

Mild steel

|

|

|

|

Stainless steel

|

|

|

|

Aluminum (with controlled use)

|

|

|

|

|

|

|

|

Applications by Industry

|

|

|

|

Automotive & Auto Body Repair

|

|

|

|

Used for grinding body panels, prepping metal for paint, and smoothing welds.

|

|

|

|

Metal Fabrication

|

|

|

|

Widely used in structural steel work, custom fabrication, and machine building.

|

|

|

|

Industrial Maintenance

|

|

|

|

Essential for repairs, part refurbishing, and surface conditioning.

|

|

|

|

Construction

|

|

|

|

Great for prepping and finishing metal components on site.

|

|

|

|

DIY & Home Projects

|

|

|

|

Suitable for home users doing repairs, restorations, or custom metalwork.

|

|

|

|

|

|

|

|

Materials You Can Use It On

|

|

|

|

Mild steel

|

|

|

|

Stainless steel

|

|

|

|

Aluminum (with care to avoid clogging)

|

|

|

|

Cast iron

|

|

|

|

Non-ferrous metals

|